Solid-State Batteries Overcome Technical Barriers—Commercialization Process Accelerates

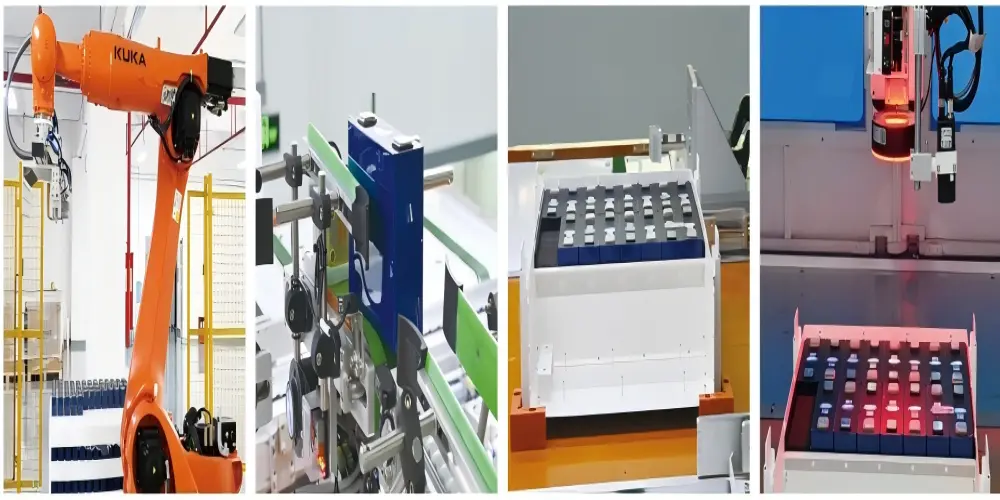

China's Battery industry has made significant strides in solid-state battery technology, with multiple companies announcing mass production of semi-solid-state batteries. This breakthrough promises revolutionary improvements in electric vehicle range and safety performance. An increasing number of enterprises are unveiling their solid-state battery technology roadmaps and commercialization timelines, signaling China's leading position in the global solid-state battery sector.

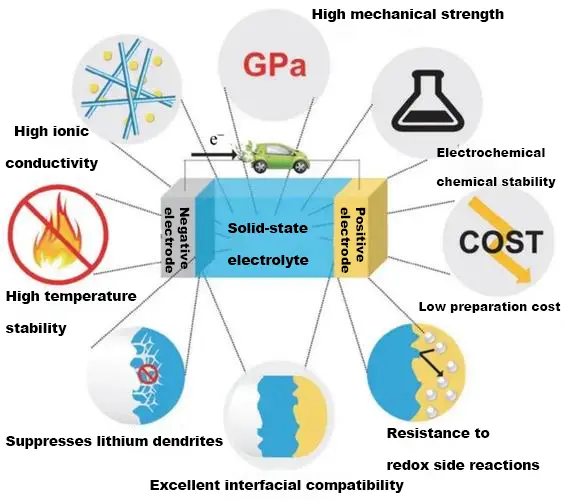

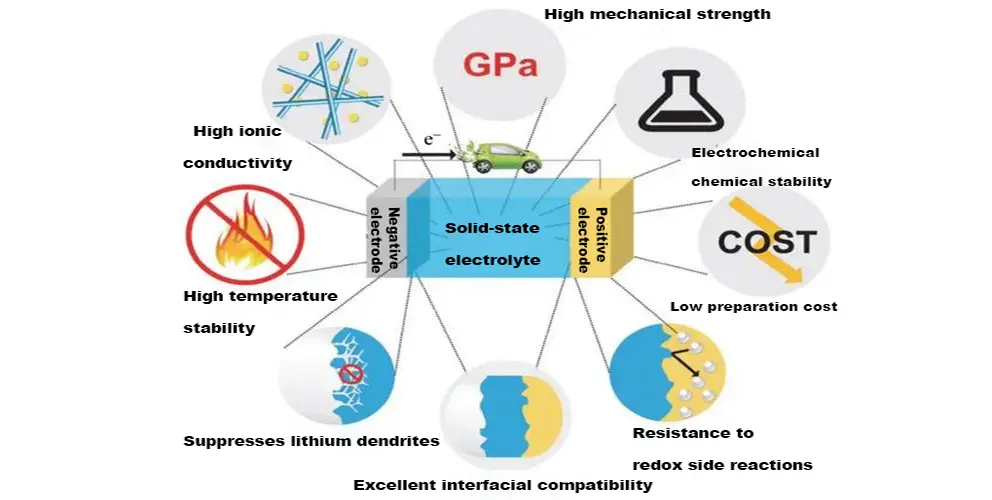

The core advantages of solid-state battery technology lie in its energy density and safety. Compared to traditional lithium-ion batteries, the most significant difference in solid-state batteries lies in the replacement of the electrolyte and the optimization of both positive and negative electrode materials. All-solid-state batteries use non-flammable solid electrolytes to replace traditional liquid organic electrolytes. Currently, there are three main technical routes: sulfide electrolytes, oxide electrolytes, and polymer electrolytes.

Solid-state batteries not only eliminate issues like leakage, corrosion, and combustion associated with liquid organic electrolytes but also permit the use of higher-capacity electrode materials. This theoretically promises significant improvements in both battery safety and energy density. When applied to electric vehicles, solid-state batteries can store more energy within the same Battery Pack size and weight, substantially extending driving range.

However, the widespread adoption of all-solid-state batteries still faces several critical technical challenges. Core materials like high-performance solid-state electrolytes in all-solid-state batteries involve relatively high raw material and process costs. For instance, the preparation and handling of key materials are highly sensitive to air, requiring specialized equipment and strict environmental control. This necessitates further breakthroughs in scalable, low-cost synthesis and preparation technologies. When silicon-carbon anodes are used in all-solid-state batteries, significant volume expansion occurs, creating interfacial impedance. Under experimental conditions, high pressure is required for the battery to function normally.

Despite these technical challenges, the commercialization of solid-state batteries is accelerating. Production line construction and mass production plans by multiple companies indicate that solid-state battery technology is on the cusp of industrialization. As the technology matures and costs gradually decrease, solid-state batteries are expected to achieve large-scale adoption between 2027 and 2030, injecting new growth momentum into the electric vehicle and energy storage sectors.

Tina - International Sales Director

Tina - International Sales Director